Pysy maun tasalla!

Finnish food and biotechnology company atSauce has achieved what many only dream of: transforming traditional craftsmanship into a modern industrial process. Founded in 2016, the company has grown into a player with over three million euros in revenue, exporting Finnish fermentation expertise worldwide.

Finnish vegetables, fruits, and berries taste heavenly when fresh, but how can you capture that authentic taste experience regardless of the season? And how could you serve the Moroccan lemon, Mexican salsa, or Chinese garlic tasted in a local restaurant to customers with authentic flavors without great effort?

By fermenting fresh, quality ingredients, anyone can enjoy intense, authentic flavors. However, there's a long way from home kitchen to industrial production, and this is where atSauce has revolutionized the world of seasoning: atSauce is the only Nordic company that has successfully scaled fermentation into a modern production process in the seasoning sector. How did they reach this point, and what did it take? Let's look back at the past years with atSauce's founder and product developer Teppo Tani. This article begins a blog series about fermentation.

From Japanese Expertise to Finnish Innovation 2016

Fermentation is one of humanity's oldest food preparation methods, and particularly in Asia, it's an integral part of food culture. After working four years in Japan, Teppo Tani realized how central fermentation was to the country's food culture and felt it needed to be brought to Finland.

"I saw concretely how fermentation brings out deeper, multi-layered flavors in ingredients. I felt that this profound yet practical approach was missing from Finland, and I decided to bring it with me," Teppo recalls cheerfully about atSauce's early days.

For Teppo, one of the most important lessons was the harmony and purity characteristic of Japanese culture, which is equally reflected in fermentation:

"I learned that flavor doesn't develop quickly; microbes need time. In Japan, fermentation is precise but also creative."

Japanese food culture, respecting patience and microbiology, has significantly influenced atSauce's product development, from building umami to texture.

“I learned that flavor doesn't develop quickly; microbes need time.

Understanding fermentation at a microbiological level is crucial in controlling industrial processes. Fermentation utilizes various microorganisms, the most important being bacteria, especially lactic acid bacteria. (Kuldjärv 2024.) "Balance, depth, and the ingredients' own voice are important to us," Teppo emphasizes. While atSauce's products' flavor profile doesn't aim to imitate Asian cuisine, it has been influenced by it.

First Steps in Product Development

Finland's pure ingredients, technological expertise, and passion for food created the foundation for a new kind of business. Product development, which began in 2016, initially focused on refining basic recipes. The first products were simple fermented flavor bases, testing how different ingredients behaved in the process. Garlic, chili, and citrus fruits proved particularly interesting for fermentation.

"The first experiments were both exciting and chaotic. Garlic produced an almost animalistic intensity. Chili fermented into something soft and deep, completely different from fresh chili," Teppo describes enthusiastically. The most challenging proved to be starchy root vegetables and very sugary fruits, as they required precise control to prevent fermentation from getting out of hand and unwanted microbes from forming. Additionally, onion was challenging due to rapid fermentation.

However, Teppo mentions citrus fruits as the biggest surprise. Their aroma deepened, and bitterness almost completely disappeared during the fermentation process. This particular moment ultimately proved valuable, as Teppo realized that fermentation, especially respecting ingredient origins, was truly unique.

"Simple ingredients produce extremely deep flavors with proper treatment,"

Teppo specifies with casual determination. This insight eventually led to an industry-revolutionizing innovation.

"Simple ingredients produce extremely deep flavors with proper treatment"

Technological Breakthrough Required Persistence

The journey from idea to implementation wasn't easy. Fermentation is a sensitive process where even small changes affect the outcome. Suitable machines for industrial production didn't exist. Development work has required determined effort, countless experiments, and unwavering faith in their vision.

One of fermentation's key challenges relates to scalability. The journey from the first successful laboratory samples to full-scale production can be long. It's critical to ensure that production yield is high enough to make the product economically viable (Tetra Pak 2025)."Initially, every batch was manual and intuitive. Gradually, we developed our own controlled fermentation environments and monitoring systems. Finally, we could scale the process while maintaining microbiological control," Teppo explains.

The idea of industrializing fermentation initially raised doubts, as no one had previously succeeded in it in the Nordic countries.

The main challenges in industrial fermentation include contamination risks, process repeatability, scalability, and raw material quality variation. Managing these challenges requires strict hygiene control, standardized processes, continuous quality control, and staff training. It's particularly important to understand how different factors affect the success of the fermentation process. (Kuldjärv 2024.)

The first 30-kilogram fermentation vessel served as a laboratory where every detail was carefully tested. The idea of industrializing fermentation initially raised doubts, as no one had previously succeeded in it in the Nordic countries, excluding the dairy industry and Bioferm. The biggest challenge was finding balance between traditional fermentation and industrial scale. They didn't want to compromise on quality or taste, even as production volumes grew significantly. "Fermentation is alive, and at industrial scale, even small variations can cause large differences. We developed our own monitoring tools, temperature control, and even new vessel structures to make the process as predictable as possible," Teppo illuminates the practical solutions to technical challenges.

Kaarina Factory Accelerated Growth

2018 was a significant turning point. AtSauce developed the first industrial-scale sauce bases and innovative packaging solutions. Every failure in development taught something new."We tested different materials and closure technologies to offer products where living flavor is preserved. At the same time, we wanted to visually communicate that this is something different from traditional sauce,"Teppo describes the first steps of growth.

He also reveals how parallel fermentation of multiple ingredients revolutionized their work:"The flavors supported each other instead of covering each other up." This led to completely new kinds of sauce and fresh flavor bases that weren't based on vinegar or sugar, but on microbiologically produced flavor constructions.

Opening the Kaarina production facility in 2021 marked a new era. Modern facilities enabled significant production increase and the launch of fresh flavor bases. The same year, the company's revenue grew by over 106 percent.

"It was a leap from craftsmanship to professionalism. Our own factory gave us full control from fermentation to packaging. We could finally make products on our own terms, without compromises,"Teppo describes enthusiastically.

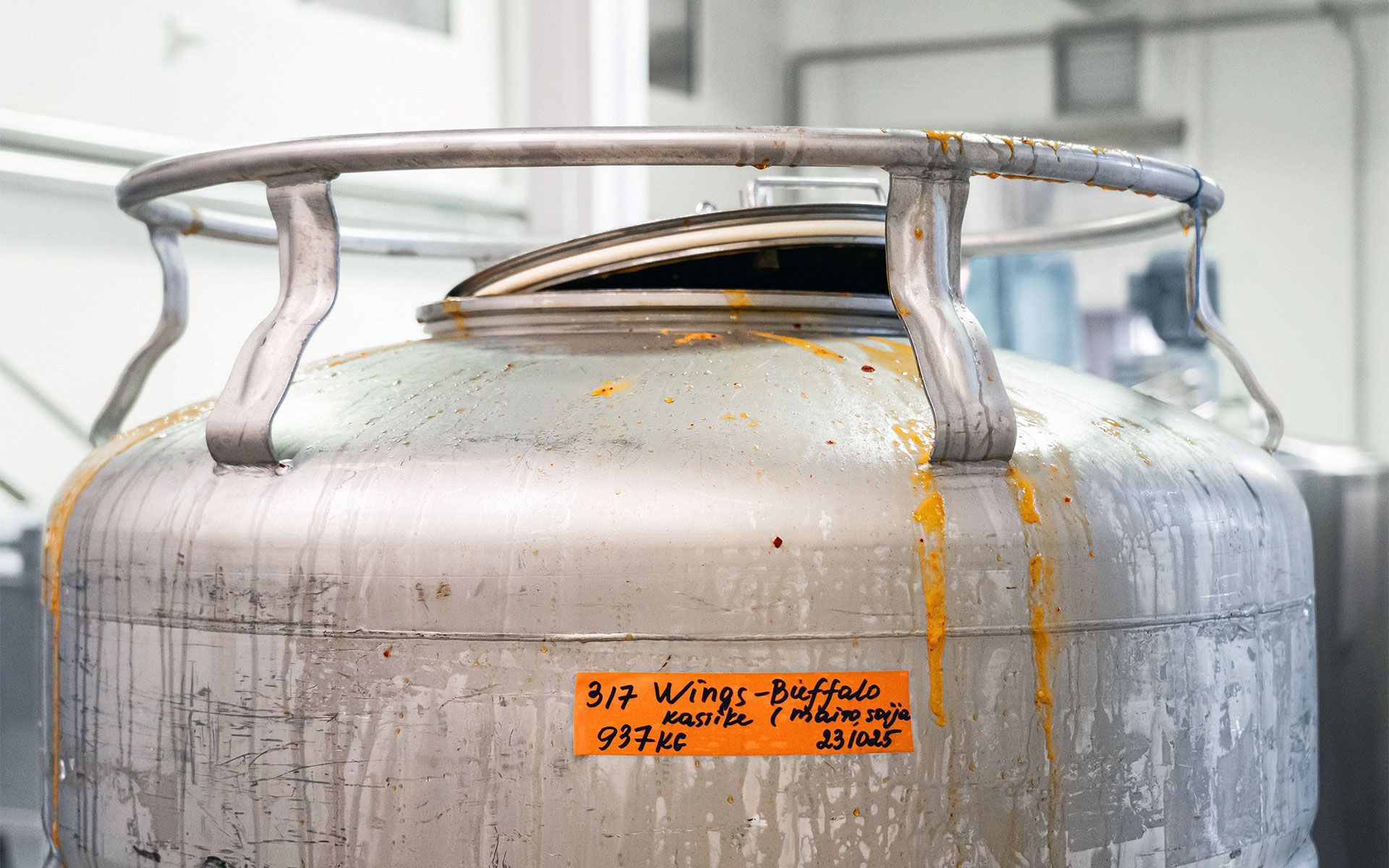

atSauce was ready to meet consumer and business customer needs for authentic flavors. There were no obstacles to growth; production was ready to take on the opportunity. New channels, collaborations, and visibility created a situation where demand grew faster than expected:"We haven't outsourced fermentation. Every batch is still in our hands. Additionally, we only use natural ingredients, and the production process hasn't been shortened." On the contrary, the production process has been developed to be even more precise, and now production uses fermentation barrels of thousands of kilos.

Looking to the Future

Fermented products are inevitably becoming part of the food industry's future, although challenges exist. Teppo reminds that fermentation isn't just a preservation method, but the core of flavor building and nutrition. Globally, it's a way to create intense flavors, preserve fresh ingredients, and produce healthy foods.

Teppo becomes excited when telling how Finland has a huge opportunity to export clean, distinctive fermented products globally:"We have pure ingredients, cold climate, and microbiological expertise. A combination that's increasingly valued."The next larger-scale goal for atSauce is dedicated:"We want to build a completely new product category: fermented, functional sauce bases that work both nutritionally and culinarily. And do it in a way that preserves our passion in every bottle and can."

Sources

Kuldjärv, R. (2024). Fermentation. Plain and Simple. Hardie Grant Books.

Steinkraus, K. H. (2018). Handbook of Indigenous Fermented Foods. CRC Press.

Tamang, J. P., et al. (2020). Fermented Foods in a Global Age: Current Research and Future Prospects. Nature Reviews Microbiology.

Tetra Pak. (2025). Enriched Beverages Through Precision Fermentation. https://www.tetrapak.com/insights/cases-articles/enriched-beverages-precision-fermentation.

Täällä jaamme tuoreimmat kuulumiset, kätevät vinkit, inspiroivat asiakastarinat ja muut herkulliset jutut suoraan meiltä sinulle. Kurkkaa kulissien taakse, nappaa ideoita omaan arkeesi ja tutustu ihmisiin sekä projekteihin atSaucen takana.